-

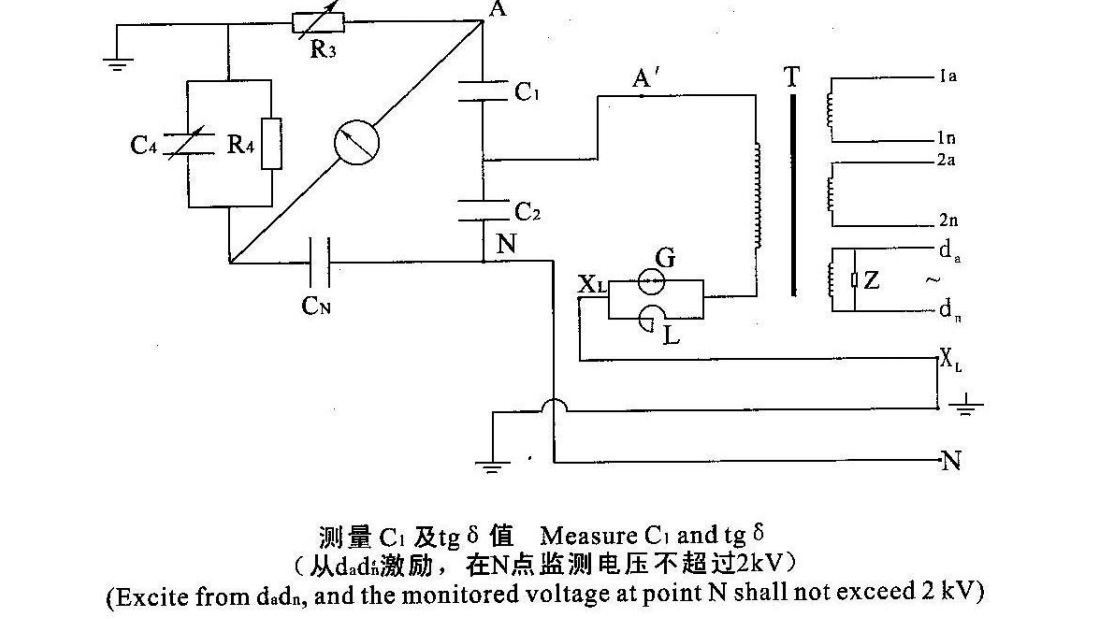

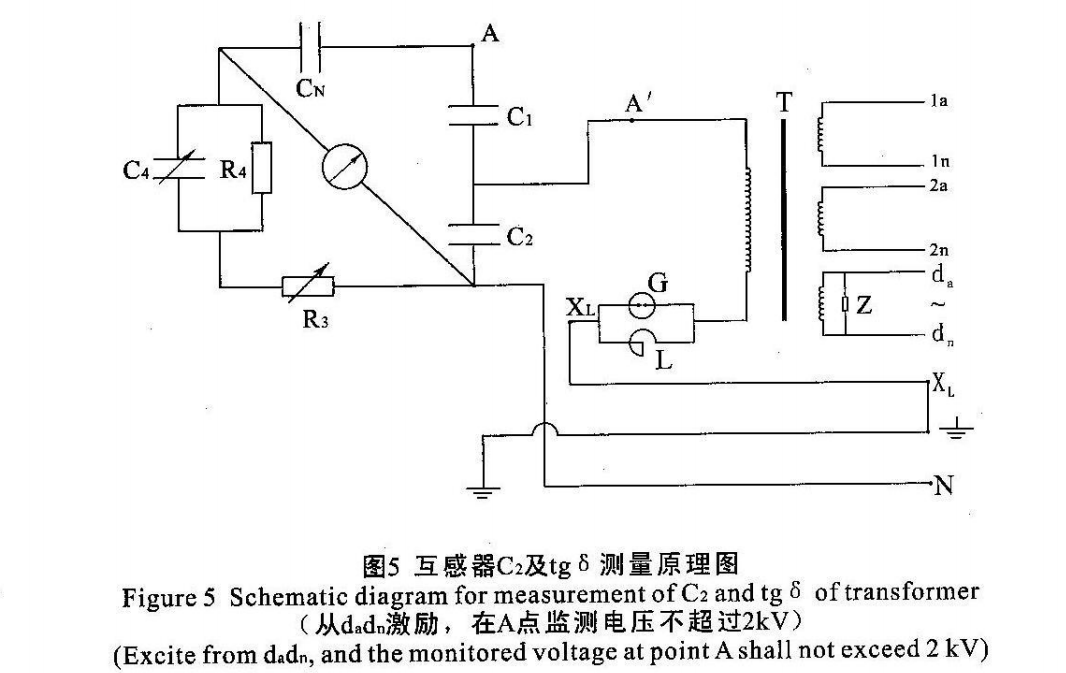

Testing is unnecessary for the transformer under normal operation conditions. Users are suggested to check the capacitance of capacitor divider and tangent value tg 5 of dielectric loss angle for each 5 years or longer time. During the check process^ the ambient air temperature shall be 25 + 10 °C, and the relative error of the equipment used for measuring capacitance shall not exceed + 3%, If the deviation between Ci, C2 and the actually measured values in Testing Records for Delivery of Capacitor Voltage Transformer- exceeds ± 10% or the tangent value tg 8 of dielectric loss angle exceeds 0.5%, the transformer use shall be stopped.

-

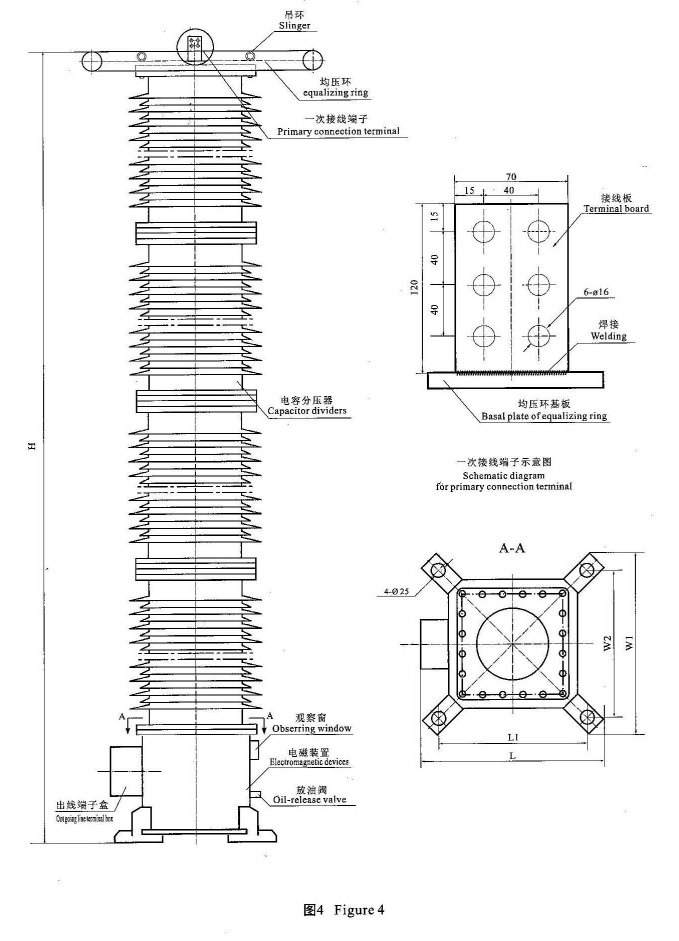

The transformer is completely sealed product with insulating oil inside. The sealing condition of the transformer shall be often checked during use process. The inspection parts include the joining between upper cover plate, lower cover plate and porcelain bush, the joining between outgoing line plate inside outgoing line terminal box and oil tank. The transformer shall not be used if there is oil leakage.

-

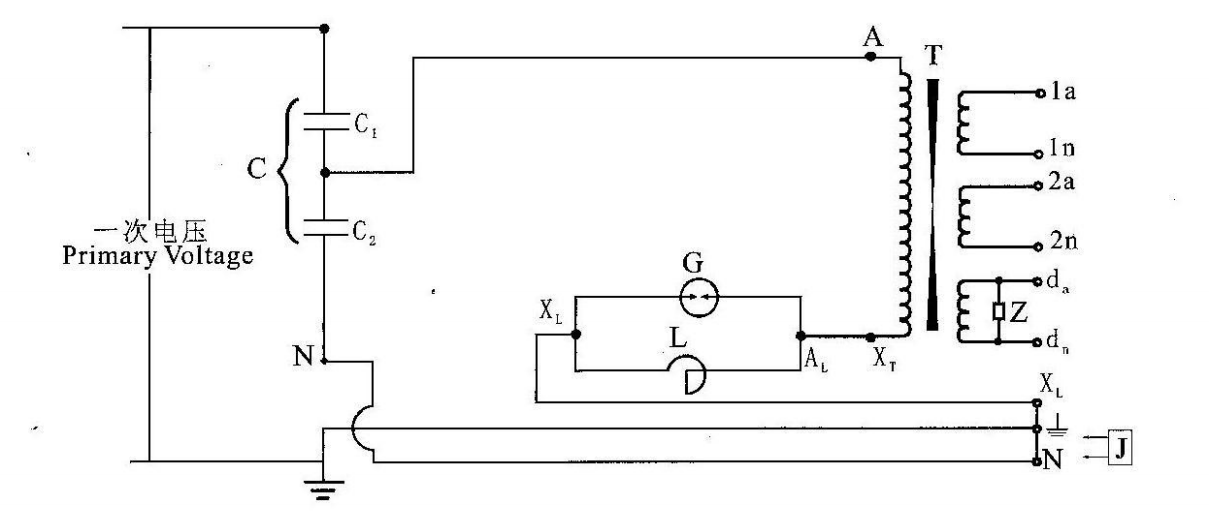

The electrical schematic diagram for measurement of capacitance and tg S i$ as figure 5. During measurement, carrier communication terminal N must be impending.

-

Self excitation method shall be used for measuring the capacitance and tg $ of capacitor divider. The excitation at the low voltage side of the medium voltage transformer can be used as testing power supply. At this time, the primary side voltage (point A or point N in figure 5) of medium voltage transformer shall be strictly monitored, so as to make the voltage not exceed the regulated value, or the parts and components in the electromagnetic device will be burned out. See figure 5 for the schematic diagram for testing.

-

Withstand voltage test for product only can be performed when necessary during acceptance and use process. For the voltage value used for test, the testing voltages for the low voltage terminal of capacitor divider, reactor and the secondary winding of the medium voltage transformer shall be the data listed in Testing Records for Delivery of Capacitor Voltage Transformer, and all the other items shall not exceed 70% of the corresponding values listed in Testing Records for Delivery of Capacitor Voltage Transformer. During the testing, the capacitor divider shall be separated with the electromagnetic device. The protective device in the electromagnetic device shall be taken off and the damping device shall be cut off. Then, voltage shall be respectively applied to the capacitor divider and electromagnetic device. Voltage must not be applied with the two connected, or the electromagnetic device will be damaged. Original status must be recovered after the testing is completed.

-

The transformer is completely sealed product. The capacitor divider and electromagnetic device must not be dismounted without the approval of the manufacturer,

-

Oil filtering or oil change is not necessary during the normal operation of the transformer. After oil sampling is performed, oil must be filled to the oil level before sampling, and 45# transformer oil can be used.