-

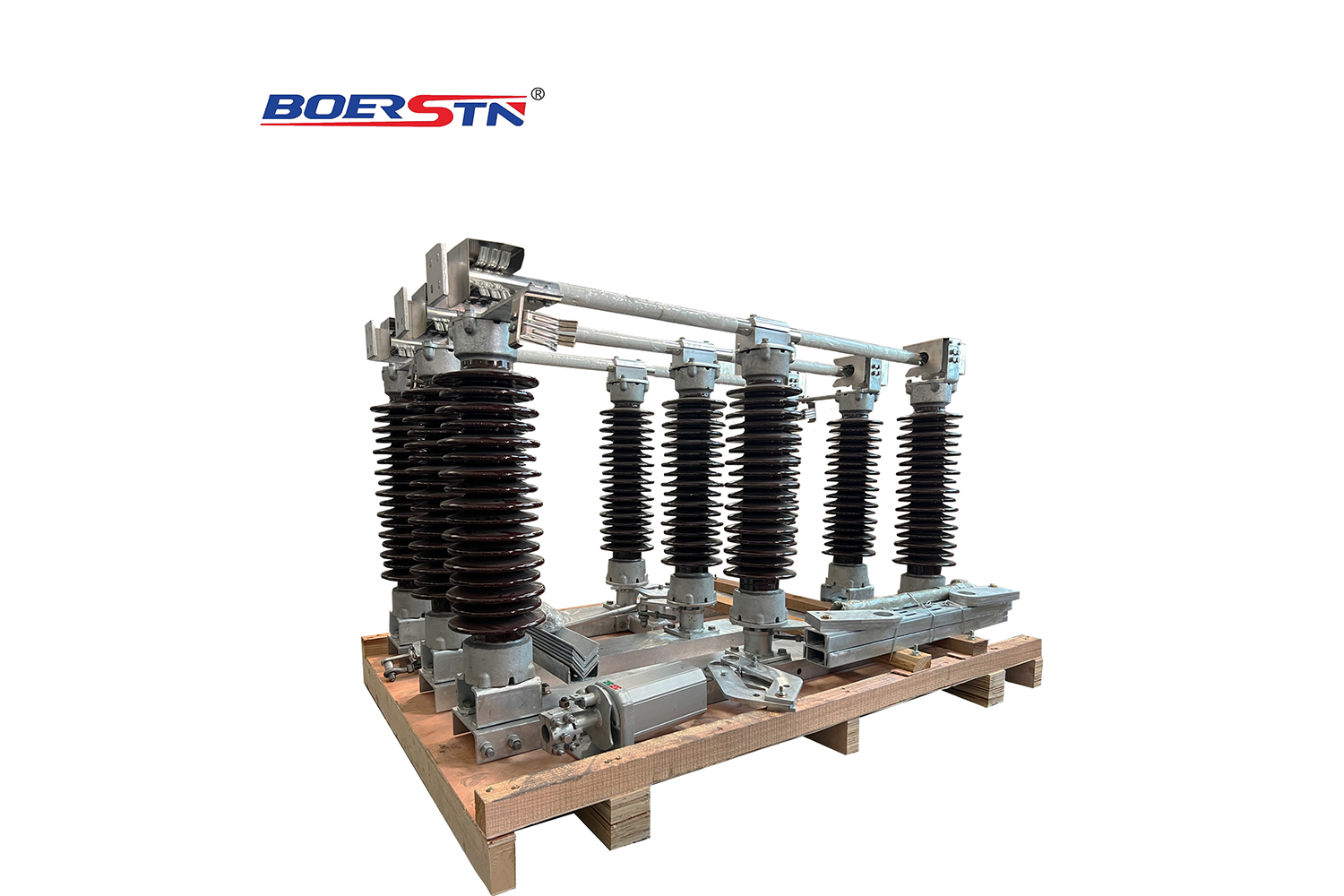

GW7-145 disconnector is a new kind of disconnector developed and manufactured by our company and based on GW7-145 technology. This disconnector is specially to solve the problem like porcelain broken , incorrect operation ,parts damage and deform ,over heat in conducting circuit,corrosion etc,to improve quality and reliability. This kind of product the design reasonable,excellent performance and has the following characteristics:

-

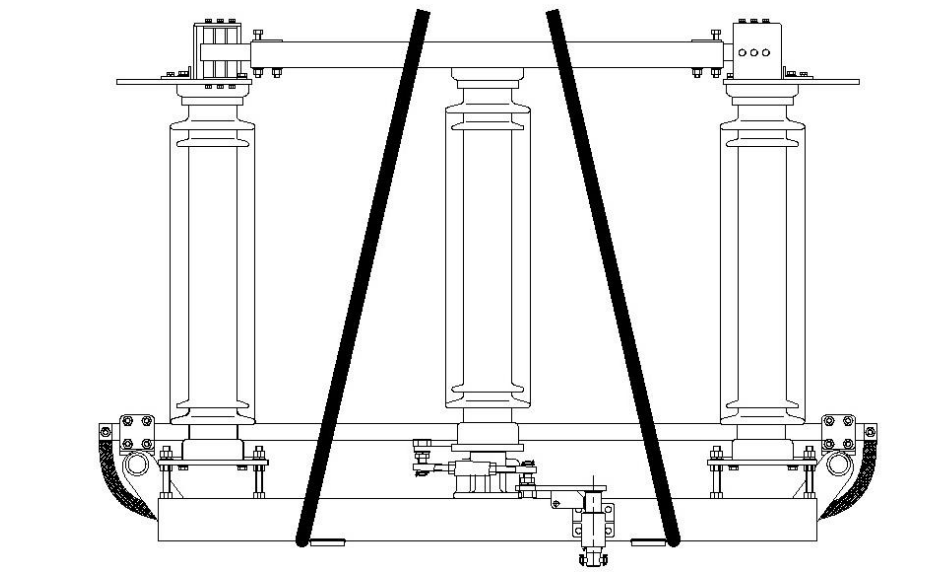

a. The conducting rod adopt the angle aluminum structure, increasing conductive cooling area ,improving conductivity reliability.

-

b.Adopt new type contacts and external pressure type contact finger structure, compare with the primary structure, the surface area of contacts and contact finger larger than before and have a good heat dissipation capability,avoid the influence of skin effect, and have better self-clean and stand wear and tear ability meanwhile. The depth of this structure of contact inserted contact finger deeper than before so that improve the conductivity reliability.

-

c.Adopt the advanced silvering technology graphite plated silver to ensure the thickness and hardness of silver coating, greatly improve the adhesive force of cladding. It is also applied appropriate contacts pressure to ensure the silver coating not fall off for long term operation.The technology of graphite plated silver improve the life of silvering parts,the silvering contact surface can work over 10000 times.

-

d.The twist link adopt the oil free self-lubricating bearing and insulating oil free bearing. The transmission link adopt hot galvanizing link bearing. The material of the all dowel adopt aluminium bronze or stainless steel and have strong anticorrosion capability , low twisting resistance, small fit clearance,transmission reliable, avoid the corrosion of spindl and ensure twist flexible.

-

e.Adopt high quality raw material or high anticorrosion surface to improve the anticorrosion capability. For example , all the surface of steel parts adopt hot galvanizing technology or stainless steel material, the material of the all dowel adopt aluminium bronze or stainless steel ,the non-conductive contact surface of contact tube adopt anodic pxidation treatment.

-

f.The earthing switch adopt single-step structure, the earthing moved contacts adopt self-reliance structure.The structure simple and beautiful,small operating force, action reliable.

-

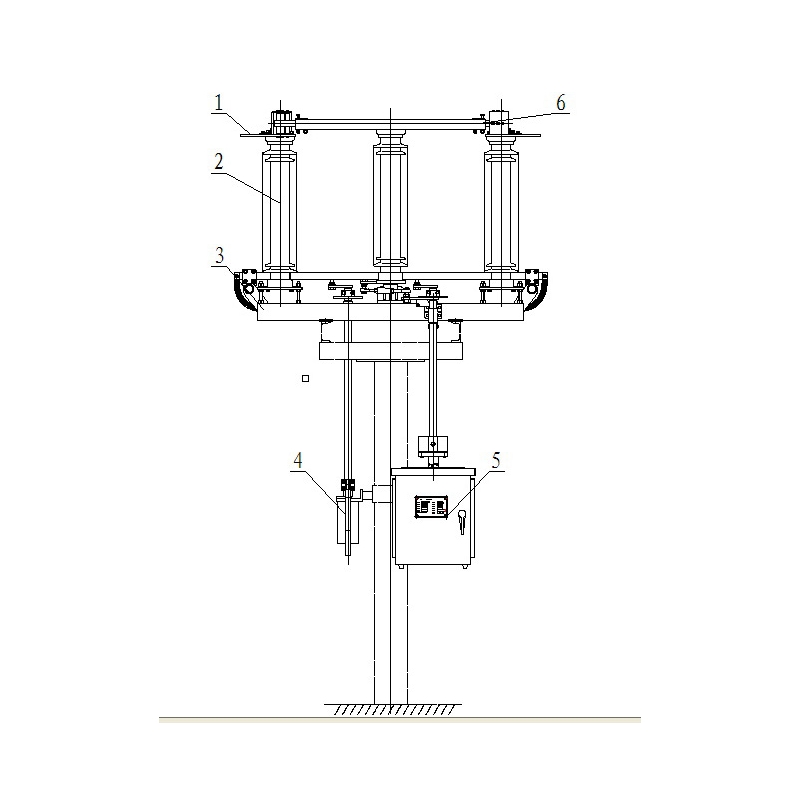

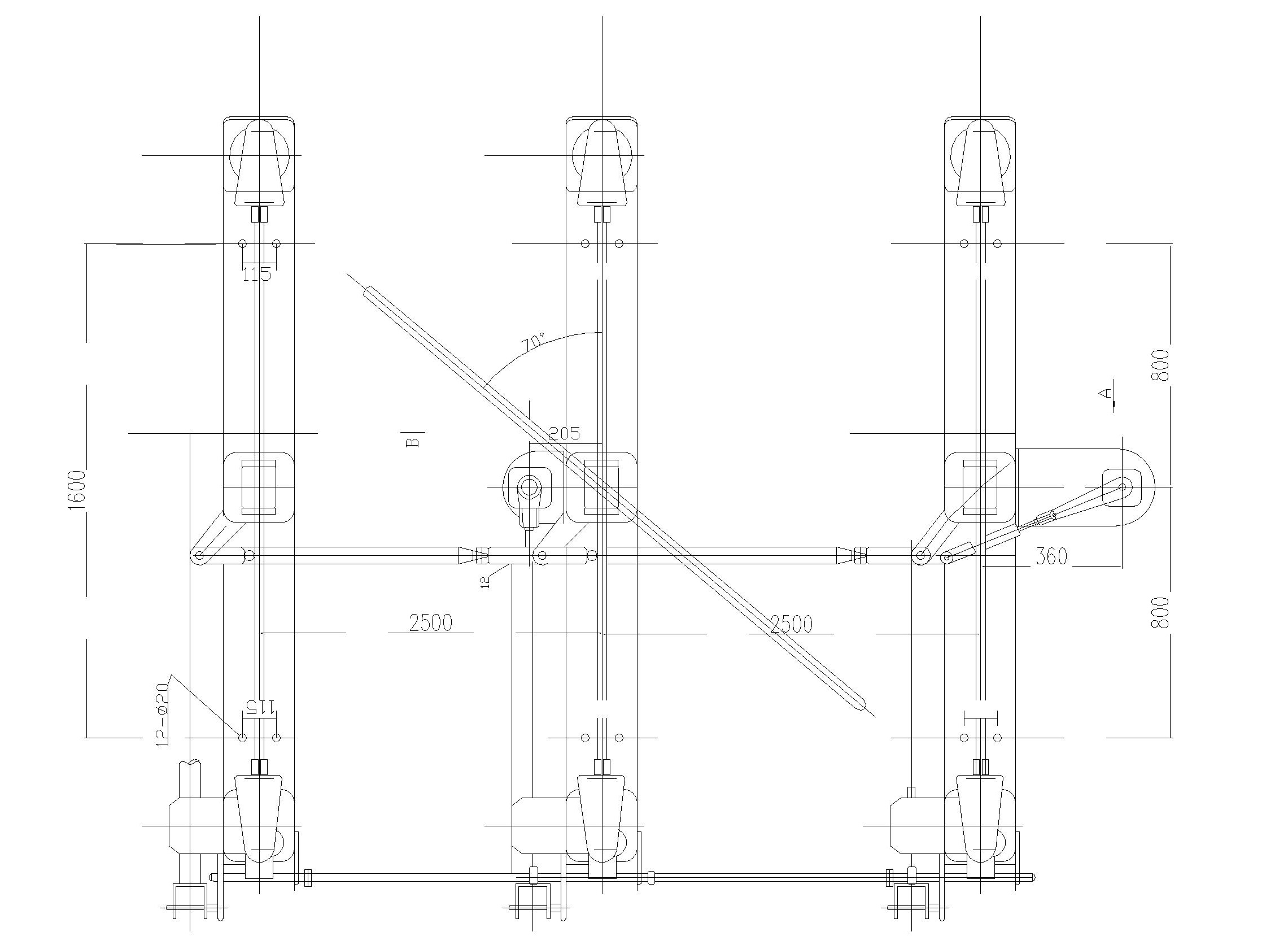

g.The connect way of vertical connecting rod which connect the mechanism of disconnector and earthing switch and noumenon and the level connecting rod which connect three phase change from on-site welded to plywood and hoop.The level connecting rod which connect main blade three phases adopt positive and negative wire connection and all can realize the infinitely variable control. Cancelling the way of welded and drilling is convenient for client to install,debugging,disassembly and maintain. It also avoid the corrosion caused by welded.

-

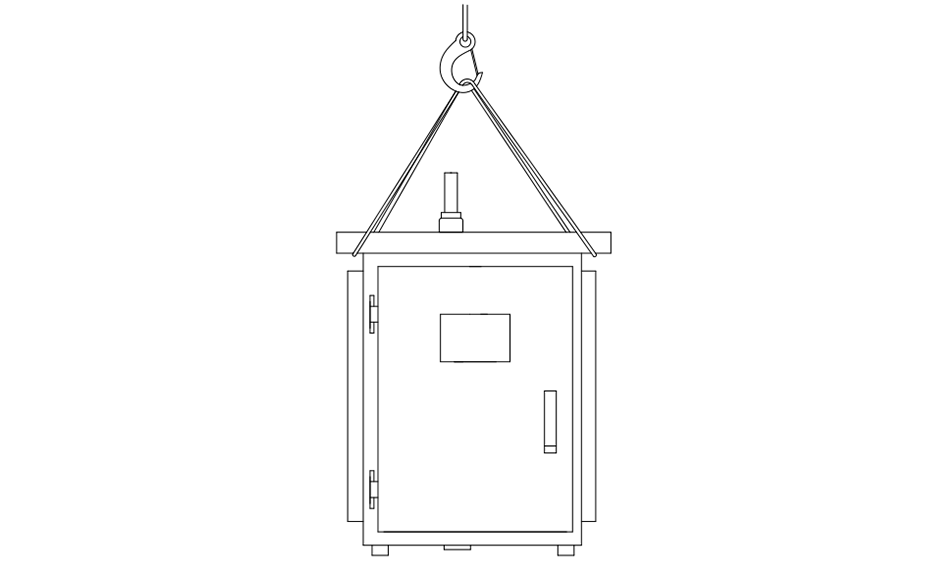

h.The motor operation mechanism box adopt stainless steel welded,the manual operation box adopt aluminium alloy material, the shape beautiful , good entirely leakproof capability. The motor operation reducing gearbox purchase famous joint stock brand, good leakproof capability , smooth operation without noise. Adopt foreign famous brand component,operation reliable , locking function completed.

-

i.Adopt the stable performance ,quality reliable post insulators and request the sintering position of porcelain exposed sand and adopt the waterproof construction so that satisfy the safety factor under 2.5 times mechanical load. Strictly select the porcelain manufacturers and take the acceptance test to ensure that the porcelain high quality and reliable.

-

j.The parts above the ground can be supplied overall according to the request and provide the galvanized steel structure and vertical ,horizontal driving rod.