-

General

●The purpose of maintenance is to ensure fault-free operation and lengthen the life. It includes the following:

Check: get a general idea of actual operating status.

Upkeep: method to keep required operating status.

Inspection: method to recover required operating status.

Note: maintenance should only be performed by skilled and careful professional technicians, they are familiar with detailed characteristics of switchgear. It is preferred that service personnel from Zhezhong will do the job.

● Check and maintenance interval of some device/components (such as wear-out parts) depends on the following rules:Running time, operating frequency and fault interrupting condition of breaker and etc. On the other hand, the maintenance period of other parts depends on working style, burden level and environmental effect of a certain occasion (including pollution and corrosive air).

● On some specific occasions, beside this M & O Manual, Instructions for Installation, Operation and Maintenance of Circuit Breakers should also be obeyed

● If necessary, contact manufacturer for detailed information.

-

Check and Maintenance

Perform check and upkeep to switchgear every 3-5 years depending on running condition and actual environment.

When running condition is abnormal (including unfavorable climatic condition) or harmful (such as serious pollution and corrosive air), the period of check and maintenance should be shortened. Check includes the following:

●Isolate workspace that check and maintenance will be performed according to safety regulations,and ensure that power isn’t on during check period.

● Check if any abnormal factor, dust or other environmental factor affects the device.

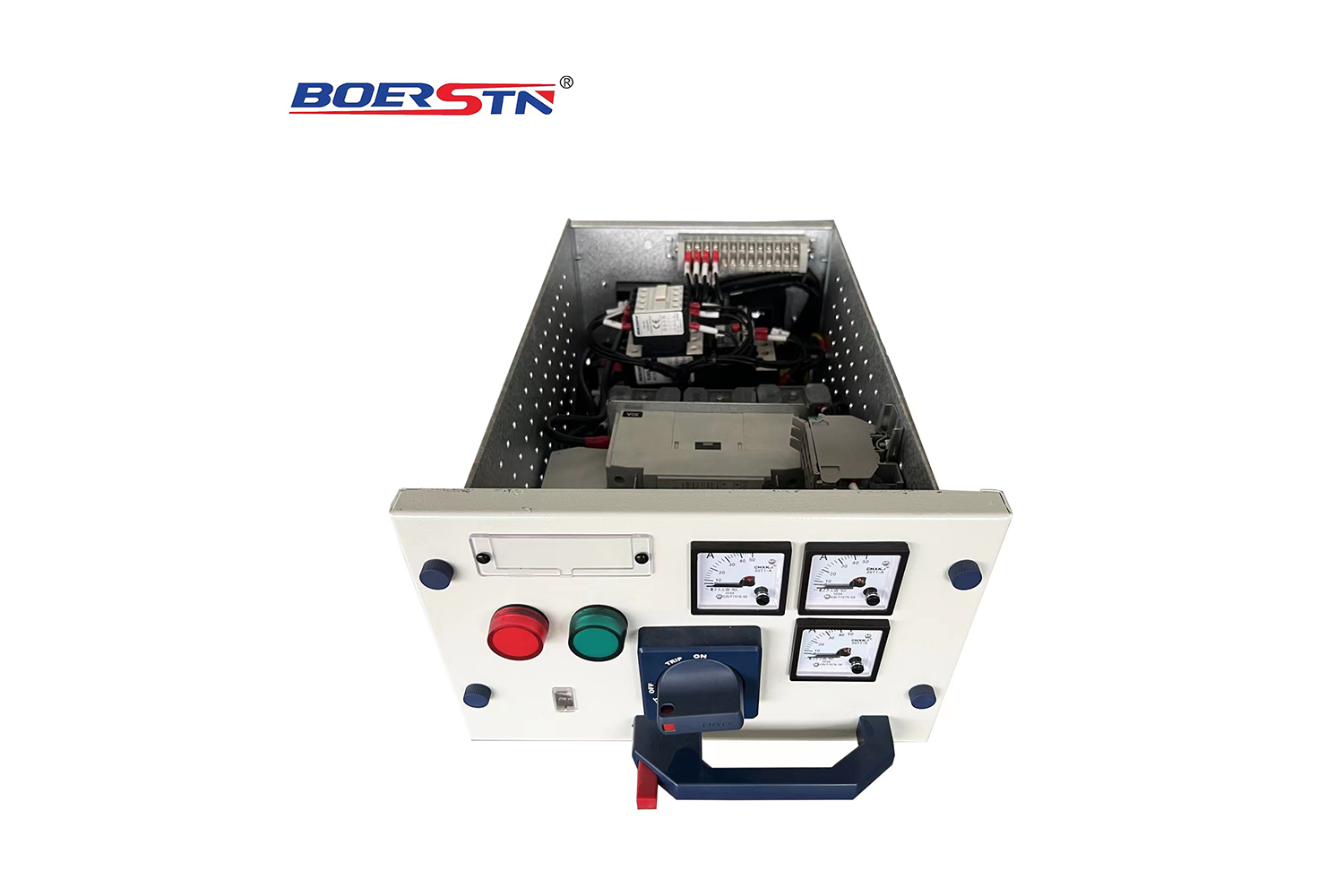

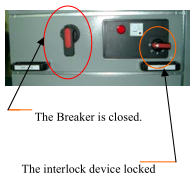

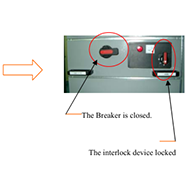

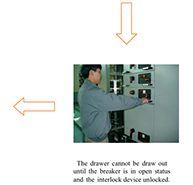

● Check the function, control, interlocking, protection and signaling of switching device and other equipment.

● Check isolating contact surface, if silver r r plate i worn out or worse, or severely corroded, or has traces of damaged or over-heated, and then contact should be replaced.

● Check accessory and auxiliary equipment of switchgear.

● At rated operating voltage, no exterior discharge at the surface. This can be judged by specific noises when exterior discharging, obviously sensed ozone smell and visible brilliance.

-

Basic check and upkeep include:

● If devices are dirty (in tropical climate, with the help of frequent moist, salt, mould, insects and conductive particles are easy to contaminate devices), then clean it carefully, especially insulating material surface. Dry and soft cloth can be used to clean dust with slight adhesion. If dust with great adhesion ( such as greasy dust), use some alkali cleanser, then the water, finally dry the device.

● As to insulating material and severely contaminated components, aseptic cleanser can be used. For the sake of safety, obey the specifications of manufacturers. Thichloroethane, thichloroethyl lene and tetrachloromethane are forbidden to be used as cleansers.

● Check if bolts of bus and earthing system are tighten, isolating contact is properly operated.

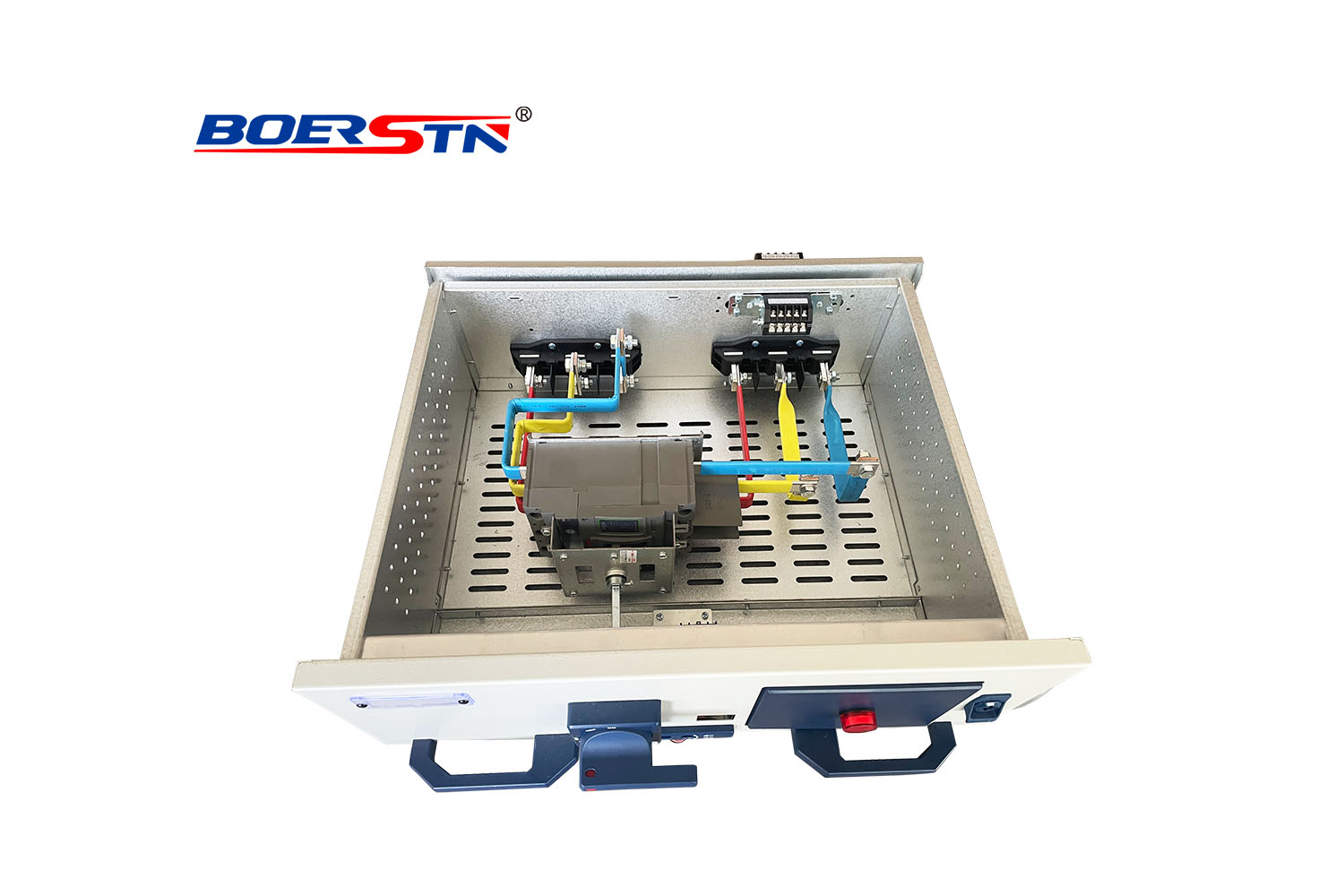

● Lubricant should be added when truck’s plug-in mechanism and contact is in short of or lack of lubricant.

● Clean the movable contact surface of switchgear (such as hinged shutter, interlocking mechanism,system levering mechanism and truck wheels), and apply lubricant.

● Observe maintenance instruction stipulated in this book.

-

Repair

General Repair

● If any defect, commit repair as soon as possible.

● Clean the rust on steel plate and other elements with mechanical method (such as copper brush).

● Rub softly the edge of paint and clean greasy dirt. Apply anti-corrosion base paint as soon as possible, after the base paint is dry, apply finishing coat. The thickness of coat is approximately 60um. Appropriate compatible paint can be used.

● Brush off the white rust spot on zinc plated or chrome plated functional element. Clean rust spot with dry and clean cloth. After installation is finished, apply base paint as soon as possible, then the finish paint. The total thickness of coat is approximately 30um. Epoxy resin base paint and polyurethane finish paint is especially applicable.

● Removable and rotating element(such as rotating shaft and link lever) don't need any paint, but lubricant should be applied.

-

Replacement of Components

When placing an order, the correct name, type, applicable current and voltage rating should be specified. Nameplate and technical instruction can be used as reference.

-

Warning

Pay attention to this instruction and safety operation regulations.

Dangerous voltage may cause shock and fire.

Cut off the power before perform any work in the live area.

● Make sure the installation, operation and service must be processed by professional electrical engineers.

● Keep legal laws, operation criterion of local power department and relevant safety operation regulations.

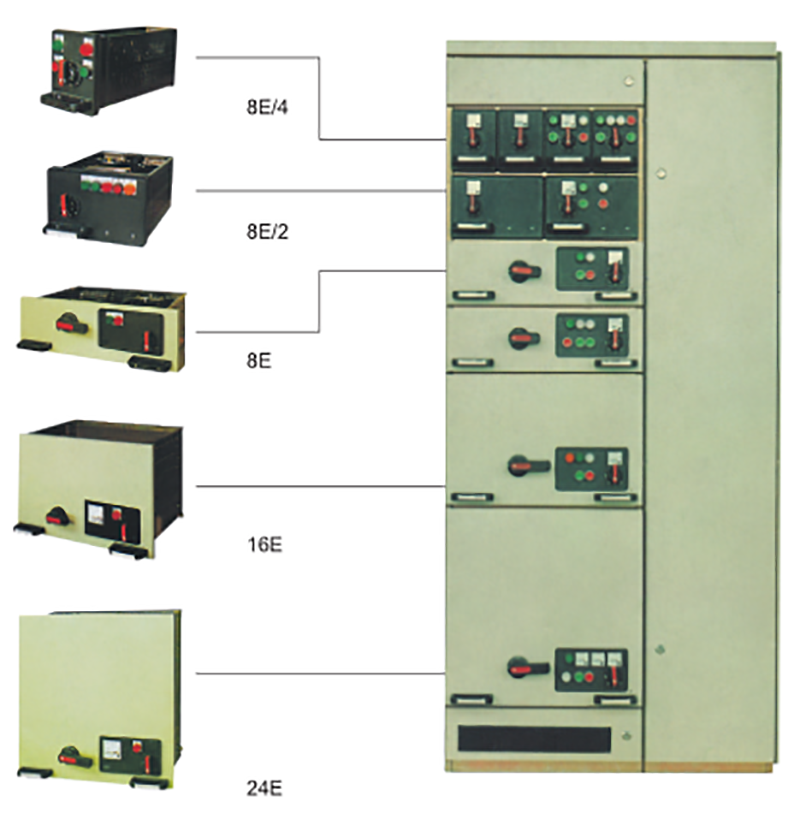

● Any activity related to GCK 、GCS、MNS switchgear should consult with this instruction.

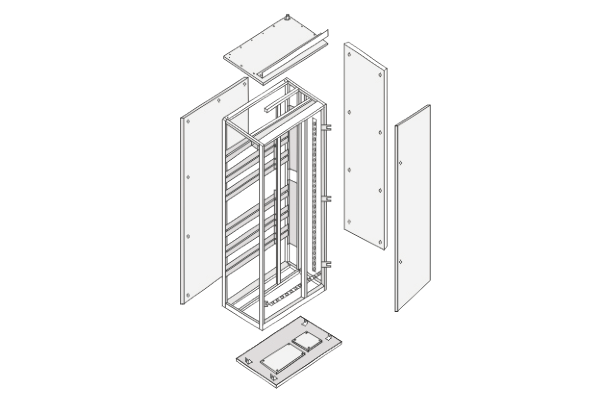

● The Low voltage switchgear is of the indoor distribution equipment, it must be installed in buildings applicable for electrical devices.

● Never exceed the rated technical data specified by switchgear nameplate.

● Make sure personnel responsible for installation, operation and service are easy to get this instruction.

● Operator should take correct and efficient resolution when any problem occurs.

● We are always glad to answer any relevant questions.