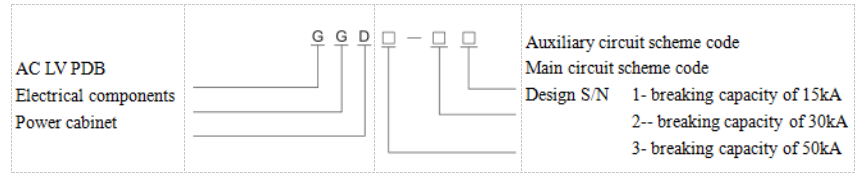

2. Main circuit scheme

The main circuit of the GGD cabinet is designed with 129 schemes, which have 298 specifications (excluding the function of the auxiliary circuit and the change of the control voltage

Among :

The main circuit scheme is for the design, use departments suggestions to select, increasing the power plant needs. Rated current to 3150A, suitable for 2000kVA and below distribution transformer selection. In addition, in order to meet the needs of the reactive power compensation designing of GGJ 1, GGJ2 capacitor compensation cabinet, its main circuit 4 schemes. a total of 12 specifications.

3. Auxiliary circuit scheme

The design of auxiliary circuit is divided into two parts: power supply scheme and power plant project, GGD cabinet will have enough space to install the secondary components, while NLS has developed special LMZ3D type current transformer to meet power plant and special user with relay protection needs.

4.Main bus

Considering the feasibility on price ratio and aluminum replacing copper , the rated current in 1500A and below, it can be used in single row aluminum busbar, rated current is greater than 1500A ,adopting double copper busbar, manufacturer is according to the provisions to produce prototype and passed the type test, of course, the production plant can also be based on user requirements to replace aluminum busbar to change the same carrying capacity of copper bus bar .

The lap surface of busbar are used soldering process

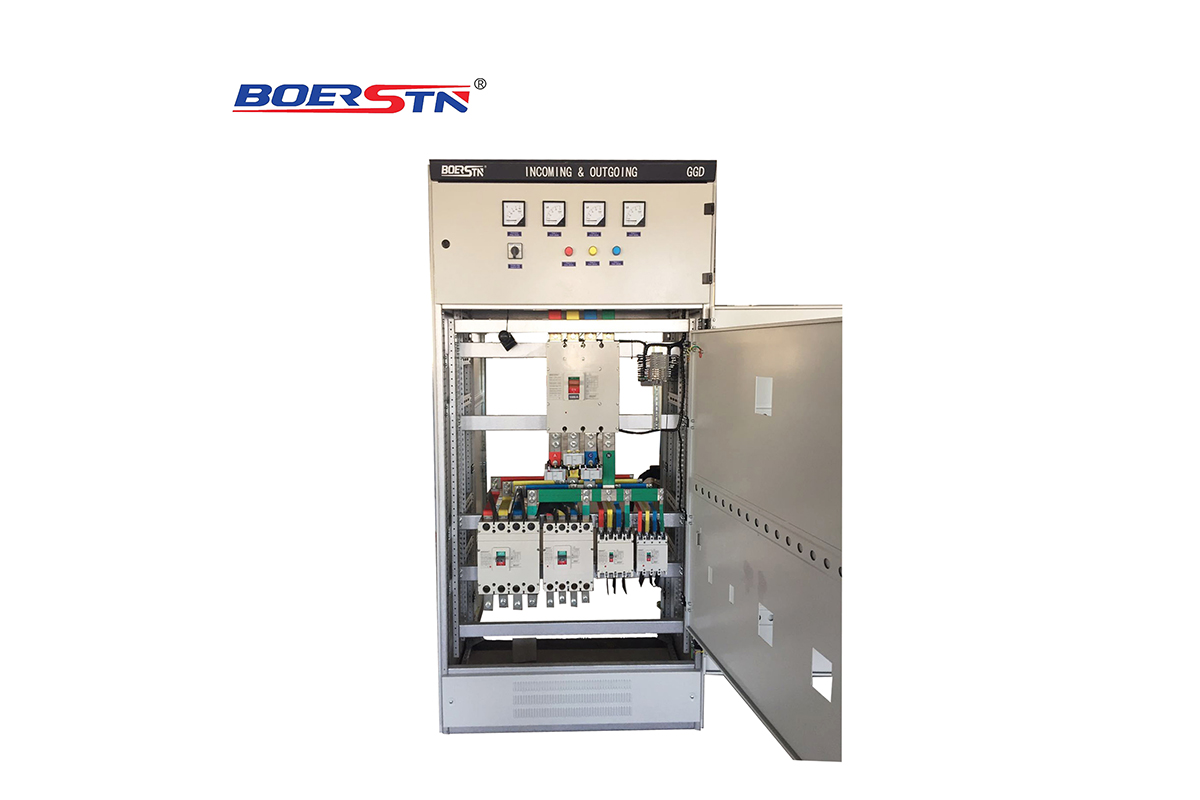

5. Selection of electrical components

(1).The GGD cabinet mainly adopts advanced electrical components , but also according to the economic and reasonable principle, retain some of the available old DZ20 in full consideration of the feasibility of the premise, such as BRM1, do not use obsolete products.

(2). HD13BX and HS13BX type rotating operation type switch is a special element NLS designed to meet the needs of GGD cabinet unique structure, it has changed the mode of operation mechanism, retain the advantages of the old products to be a practical new type of electrical components.

(3).As the design department according to user needs, with more excellent performance, new electrical components, more advanced technology, because the GGD cabinet installation flexibility good, generally will not cause the difficulty of manufacturing and installation of the update for the electrical components.

(4). norder to further improve the dynamic stability of the main circuit, NLS designed the ZMJ type bus GGD cabinet special clamp and insulating support parts. Bus clamp is made of high strength, high flame retardant Pp0 alloy material, thermoplastic molding, high insulating strength, self extinguishing performance, unique structure, only need to adjust the block between the block easily combined into a single or double busbar busbar clamp clamp, insulating support sleeve is molded structure, low cost, high strength, the old product creepage distance is not defective.