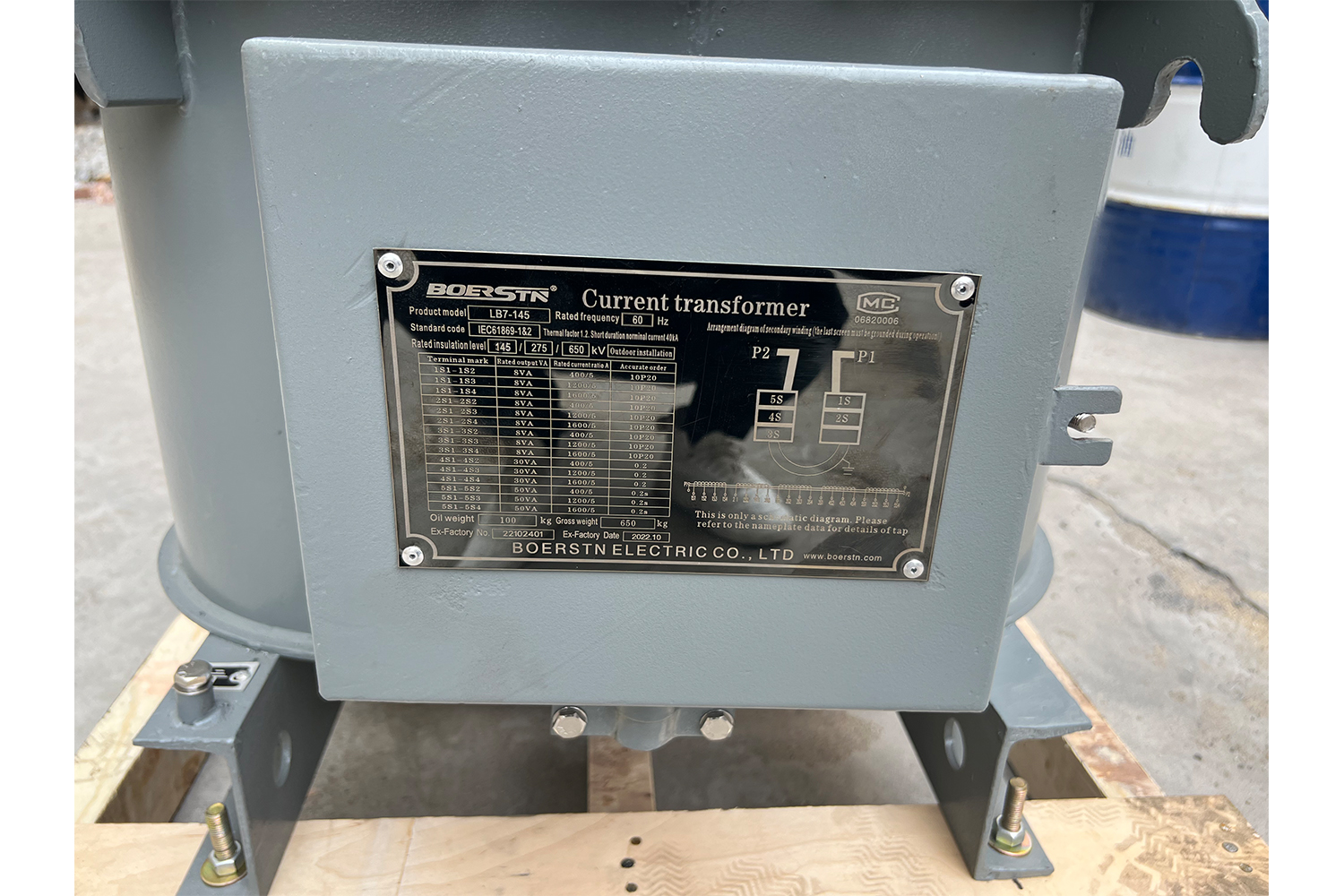

3.11 Instrument security factor for metering cores: Fs < 10

3.12 Accuracy limit factor for metering cores: 20

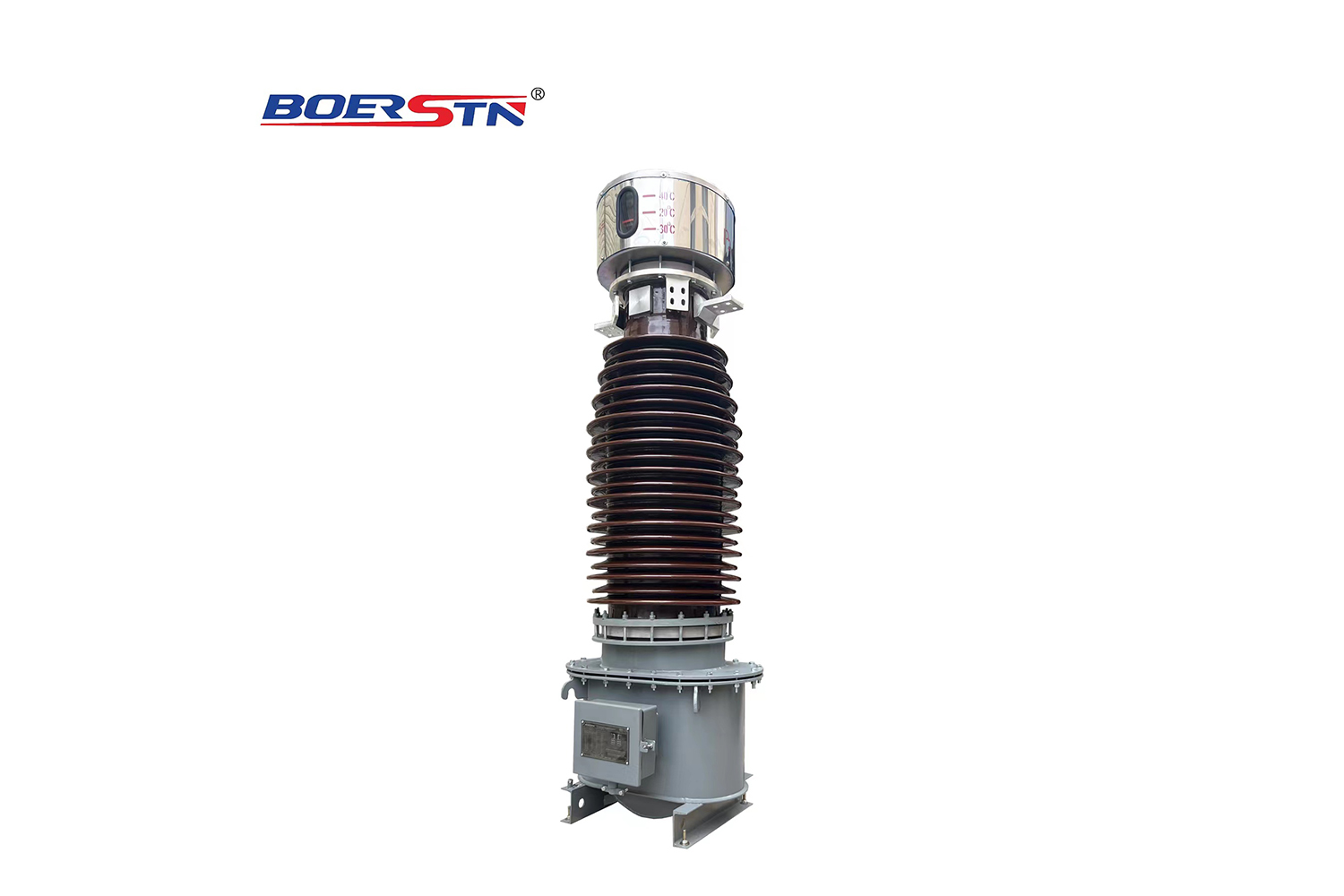

3.13 Limits of Temperature rise

The temperature rise of the current transformer when operating for a long term under rated primary current and rated output, shall not exceed the limiting value shown in the following.

a. Temperature rise of the windings: 65K

b. Temperature rise of the top layer of oil: 55K

c. Temperature rise of exterior terminal (Pl, P2) or interface of the windings: 50K

5. Insulation performance requirements

3.1 Short-time power frequency withstand voltage

a. Short-time power frequency withstand capacity on secondary windings and end shielding to earth: Applied voltage on winding-to-winding and winding-to-earth shall be 3 kV / 50 Hz / 1 min, and the shielding-to-earth shall be 5 kV/ 50 Hz / Imin.

b. Short-time power frequency withstand capacity between the primary windings: Applied voltage between the primary winding sections shall be 3 kV/ 50Hz / 1 min.

c. Short-time power frequency withstand capacity on primary winding: Applied voltage on primary winding to secondary windings and earth shall be 230 kV 50 Hz /I min.

d. External insulation short-time power frequency withstand capacity in dry and damp conditions shall be 230kV / 50Hz / 1 min.

3.2 Lightning impulse withstand

Full impulses: 1.2/50P-S 550 kV (Peak)

3.1 Inter-tum insulation strength

The rated withstand voltage for inter-tum insulation shall be 4.5kV(Peak).

3.2 Capacitance and Dielectric dissipation factor(tan 8 )

3.2.1 The value of dielectric dissipation factor should be referred to a voltage level in the range from lOkV to Um/V3, tan 8 <0.5%.(Um=126kV)

3.2.2 Applied voltage on end shielding to earth is 3 kV /50 Hz, tan 8 < 2%.

3.3 Partial discharges

Applied a voltage level with Um, PD < 10 pC; Applied a voltage level with 1.2Um/V3,PD

3.4 Rated short-time thermal current (Ith): 45kV/ Is

Rated dynamic current (Idyn): 126kV

3.5 Performance requirements of transformer oil

Transformer oil shall meet the requirements of the corresponding items of the standard IEC 60296:2003

Transport, storage, installation and test

5.1 This current transformer shall be foxed inside the packing box, and the transportation only can be performed after the packing is completed. The equipment injuries when dropped down or toppled over in transportation, do not transport it in any other than the specified way, and collision and other mechanical damages shall be prevented.

5.2 Transportation way: Vertically foxed to transport

5.3 When receiving packages, all packages should be inspected for their appearance based on the packing list prior to acceptance. And then unpack the box (remove the top and side plates of the package while special caution must be taken not to damage the porcelain bushing) to inspect the equipment carefully, you should check whether there are damages during transportation such as porcelain bushing broken, oil leakage or deformation and so on, and also check whether the spare parts and technical data or documents are complete. Please contact our company immediately if you find something wrong, so we can investigate the cause and properly handle it in a timely maimer. After the inspection, please return the equipment to the state in which it was transported as best possible to store the equipment safely.

5.4 The equipment shall be stored in the places with a ambient air temperature

of - 25°C〜+50°C, and there shall be no fire goods, explosive substances,

corrosivity and serious concussion. Water should be quickly and completely drained form the ground in case of outdoor storage. The equipment should be raised about 10cm above the ground by placing wooden blocks under the package for the purpose of securing better ventilation and protecting the packages and the equipment form immersion and rain. During ling-term

storage, you should check the performance of oil level and sealed condition periodically, handle it immediately if you find something wrong. The guaranteed valid period of packages of equipment is about 12 months after shipment. In case of packages to be stored after the valid period, such packages should be immediately unpacked and equipment should be properly treated by moving it inside the warehouses after making inspection.

5.5 Remove the bolts for foxing the CT to the bottom plate of the package, and fasten 4 wire ropes of same length to the lifting hooks on the oil tank (don't lift the CT on the top of it). The main wire ropes must be bound by using another rope or strap to avoid the main ropes loosening. The CT's top cover should be protected from damage by felt rings or rubber cushions. And then slowly lift the CT and move it to the supporting structure. Fix the CT by the attached mounting bolts. The hoisting shall be slowly and stably performed to prevent the action of impact force.

5.6 Examination before installation

5.6.1 Appearance inspection: Inspect the CT carefully, maybe find damage during transportation such as porcelain bushing broken, oil leaking or deformation and so on .

5.6.2 Check the performance of oil level, if the level lower than the normal line, you should add qualified transformer oil with the same brand in time.

5.6.3 Check the paint surface of metal fittings, if the paint comes off, you must touch up the chipped paint on it as early as possible.

5.6.4 Before operation, acceptance test shall be conducted according to the requirements of the contract and corresponding standard items: Insulation resistance measurement, capacitance and dielectric dissipation factor measurement, transformer oil test, volt-ampere character measurement, polarity check, current ratio measurement and so on.

5.5 Installation Notes

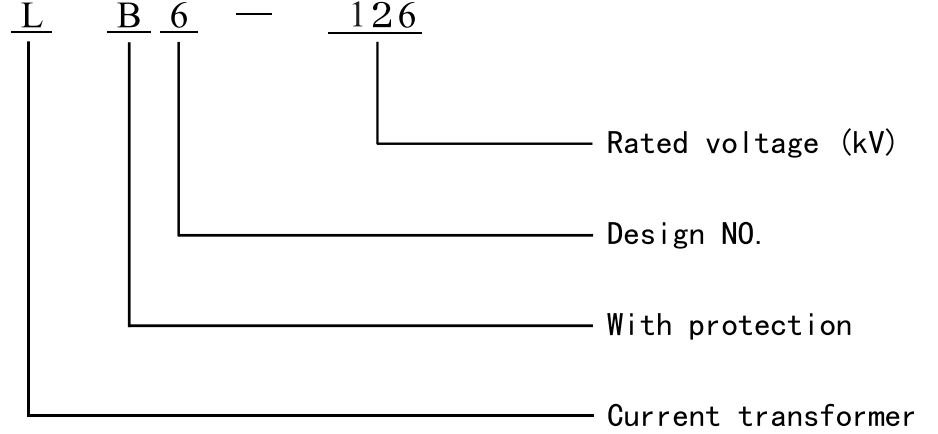

5.7.1 Before operation, the current ratio made by the connection of primary terminals in series or in parallel and connection of secondary terminals, which must be checked whether complies with the requirements of your operation. Regarding the connection methods, you can refer to the wiring diagram on the nameplate. All fixed fittings must be screwed tightly in order to preventing bad contact, which could cause a high temperature rise or secondary terminals open. If only can be allowed the connection in series or in parallel for the equipment, you should not change the primary terminal already connected.

5.7.2 The secondary leading cable must pass through the tube under the secondary terminal box (a round lid on the middle of the oil tank). The diameter of the cable shall be less than 40mm. After the cable getting through the tube should be connected with the secondary terminal, and then fasten the lid tightly. Use insulated tape to bind up the tips of the cable and fix it firmly with the clamp.

go around the Ring Core, set in the bottom of primary winding and placed in the oil tank; secondary winding terminal box is located in the front of oil tank, oil valve for draining is located at the bottom of oil tank. Metallic bellows is installed at the top of

5.7.3 Each secondary winding of the equipment shall not be allowed to open. If one of secondary winding is not used temporarily, you must make the secondary terminals to be short-circuited. The primary end shielding terminal and the earth studs on the oil tank must be earthed reliably, so that the equipment can be put into operation.